- Home

- Retrofitting and Reverse Engineering

REFURBISH, RETROFIT, AND REVERSE ENGINEER

Retrofitting and reverse engineering are specialized services not typically offered by most distributors. When equipment fails and replacement parts are no longer available, users can find themselves in a difficult situation. What should you do when reliable equipment breaks down and cannot be repaired? The answer is simple: reach out to CDWdrives. Our team specializes in retrofitting and reverse engineering, ensuring your equipment is operational again without costly replacements.

Part obsolescence is a significant challenge for manufacturers today. The expense of completely replacing machinery and parts that have become "obsolete" due to new technologies can be daunting. Fortunately, CDWdrives provides retrofitting and reverse engineering services that enable you to upgrade older technologies to meet current specifications, allowing your equipment to perform at its best.

Our dedicated services deliver precisely what you need, when and where you need it. We are more than just a catalog; our experienced engineers are here to tackle your challenges and provide effective solutions. Trust CDWdrives to extend the life of your equipment and save you money in the process.

Reverse Engineering

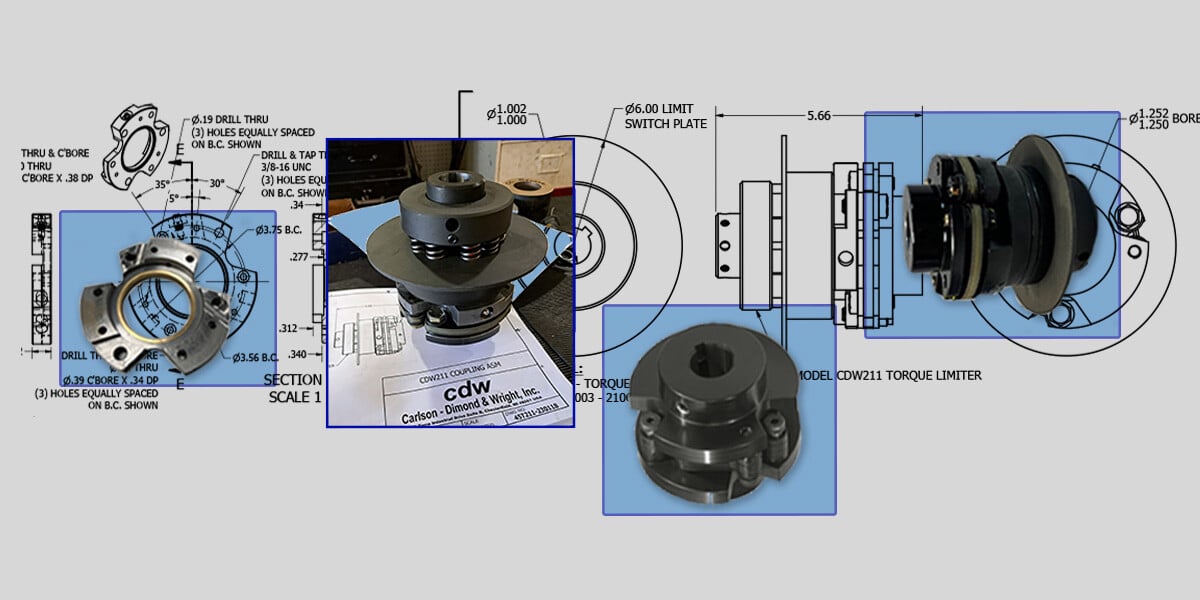

Modified CDWdrives Torque Limiter

The CDWdrives team of engineers and service experts bored and added a custom bushing to an in-stock CDWdrives 211 torque limiter. They also custom-machined a plate to attach a high-quality Zero-Max flexible shaft coupling. This solution saved the customer both time and money on the repair, and the new components will improve efficiency.

Reverse Engineering

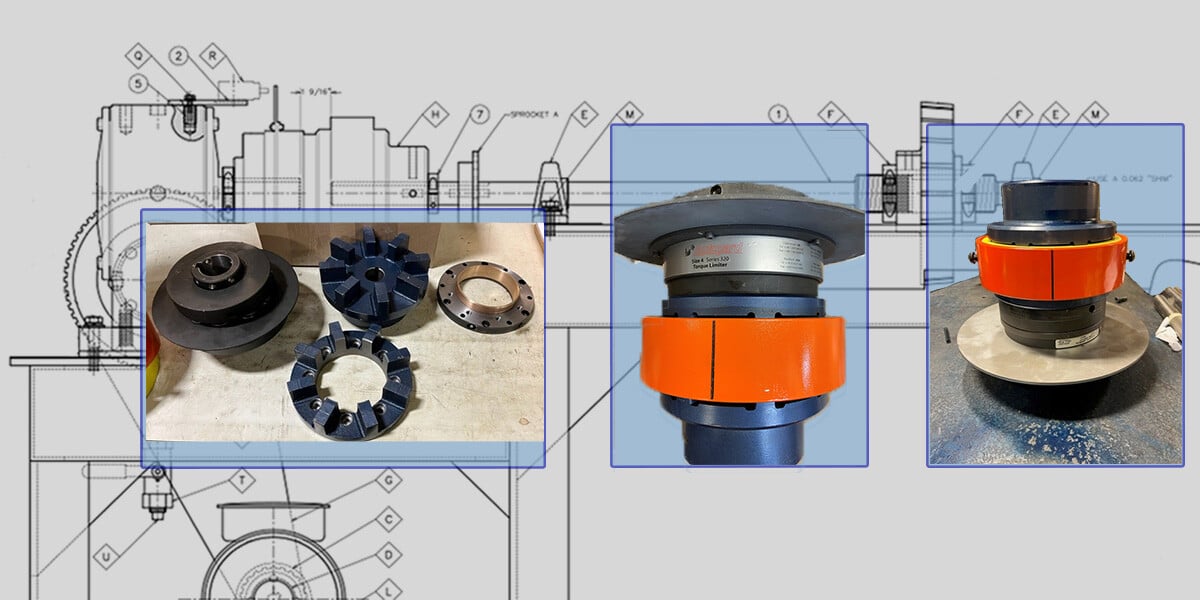

CDWdrives Torque Limiter + Samiflex Couplings

We reverse-engineered an assembly that was soon to be obsolete. The CDWdrives engineers and service team got them back up and running in 1/3 of the time compared to what it would have taken to replace the entire assembly, and at a much lower cost. Our solution worked so well that our customer is standardizing this assembly on dozens of their machines to avoid future component failures.

Reverse Engineering

Replace Obsolete Components

Problem: The customer needed to replace a broken, obsolete worm gear reducer and torque limiter with long lead times. They wanted to reuse the existing input gear stage and bracketry. Solution: We reverse-engineered and selected a new Nord Gear Flexbloc series reducer that fits seamlessly with the existing components. The customer easily and quickly assembled the input gear stage to the new reducer and mounted a CDWdrives torque limiter with a custom bore and sprocket.

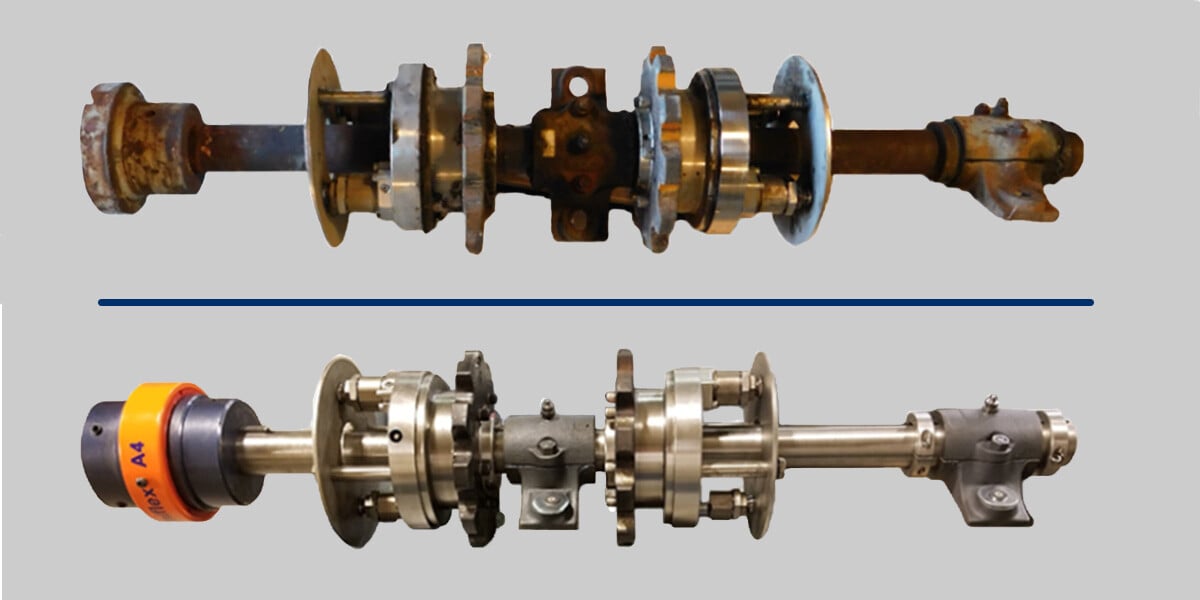

Refurbish

Water Treatment - Deteriorated Peak Cap Bearings

CDWdrives is your water treatment solution provider. We provide unique services that set us apart from other companies in the industry. We refurbished peak cap bearings used in a rectangular clarifier at a wastewater treatment plant, saving time and money. We quickly got their primary tank back up and running 24/7. Get in touch with CDWdrives and experience for yourself why our customers choose to come back to us time and time again.

Retrofit, Refurbish and Rebuild

Rectangular Clarifier Drive Shaft

We retrofit new components cost-effectively when existing parts are unavailable, restoring and adding new functionality to your equipment. When CDWdrives rebuilds and refurbishes your older equipment, it will perform like it did when it was new. We can determine the best, most efficient options to get your equipment back up and running.

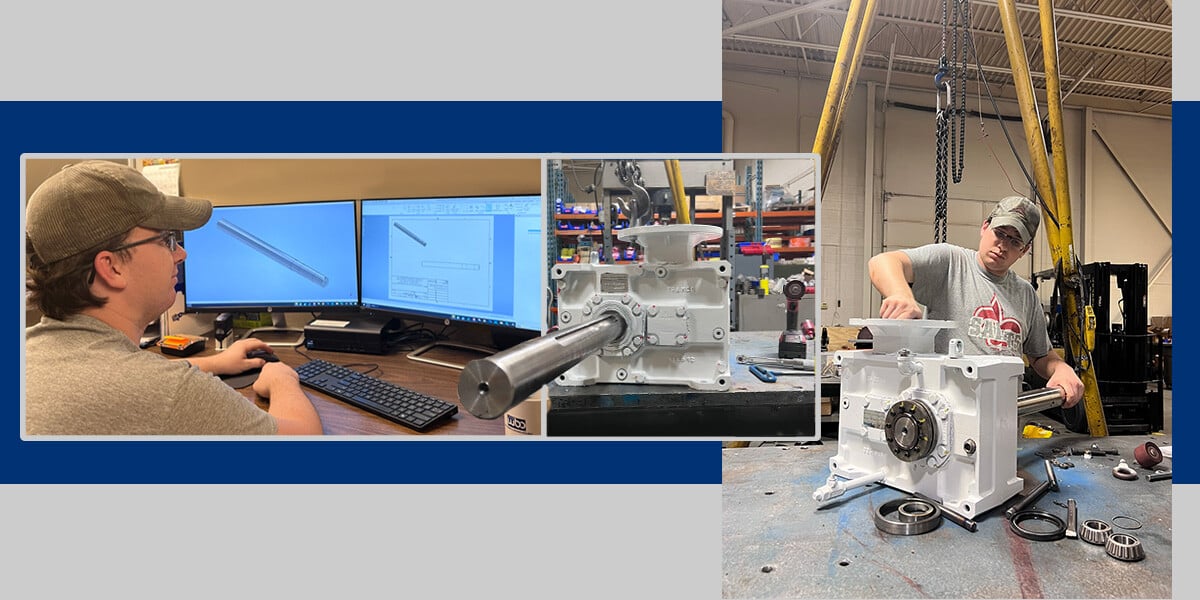

Engineering Services

Reverse Engineered custom component for replacement

Due to its unique specifications, we could not replace the damaged custom tapered shaft with a standard shaft. To address this issue, we reverse-engineering a replacement shaft. This new shaft, which we meticulously designed and built, integrated seamlessly with the gearbox we had rebuilt. This approach ensured that the replacement met the necessary functional requirements and maintained the integrity and performance of the entire system.