SAMIFLEX - ELASTIC STYLE COUPLINGS

SAMIFLEX Couplings and Inserts

A maintenance-free solution that reduces expensive downtime. Samiflex couplings are designed for easy inspection and replacement. You can quickly remove and replace the insert without moving the driving or driven equipment.

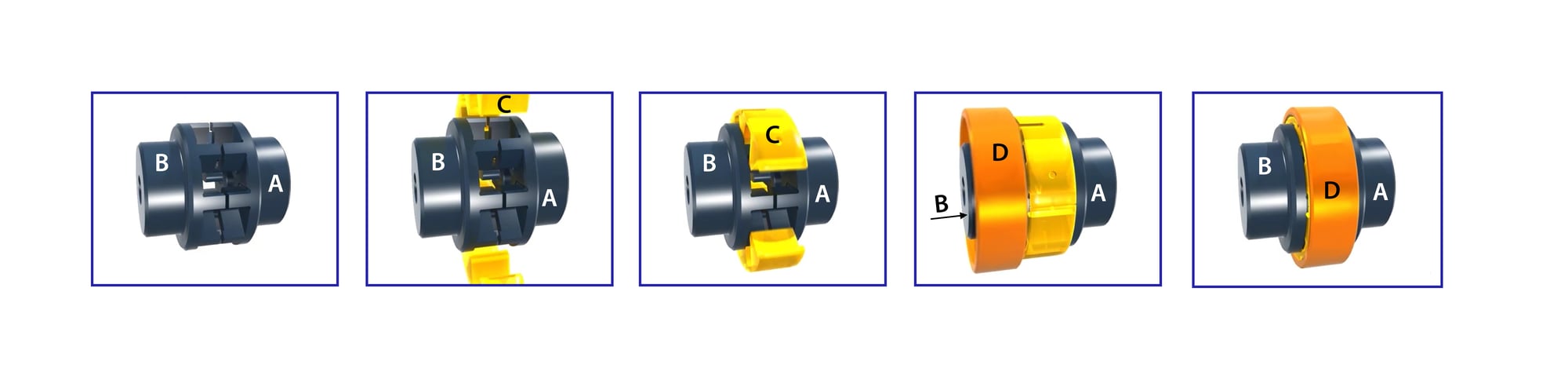

Assembly and Replacement are As Easy as One, Two, and Three.

-

Align hubs (A) and (B) on the shafts.

-

Insert the elastic insert (C) into the parallel slots between hubs (A & B).

-

Slide a polyamide or steel retaining ring (item D) over the insert, securing the insert and ring between the hubs. Retaining rings are provided with locking screws as standard.

Once the hubs (A and B) have been installed and aligned on the shafts, the coupling hubs will not have to be moved again during the life of the equipment. The insert is quickly and easily removed and replaced without the need to undo screws, bolts, or other fasteners (no special tools required) by simply sliding the retaining ring (D).

.png?width=396&height=320&name=images%20(no%20background).png)

More Samiflex Coupling Advantages

- Maintenance Free - No lubrication is required over the life of the insert.

- You can rotate the hubs independently during a motor test.

- No metal-to-metal contact.

- Large bore to torque capacity.

- Vertical operation is possible with standard coupling.

- Retaining rings are provided with locking screws as standard.

- The standard insert can handle an extensive temperature range from -40 to 80°C (-40 to 180°F).

- High-temperature inserts are available up to 150°C (300°F).

- Polyurethane insert is very resistant to chemical attack.

- Polyurethane insert hardness options are available to optimize torque capacity and damping.

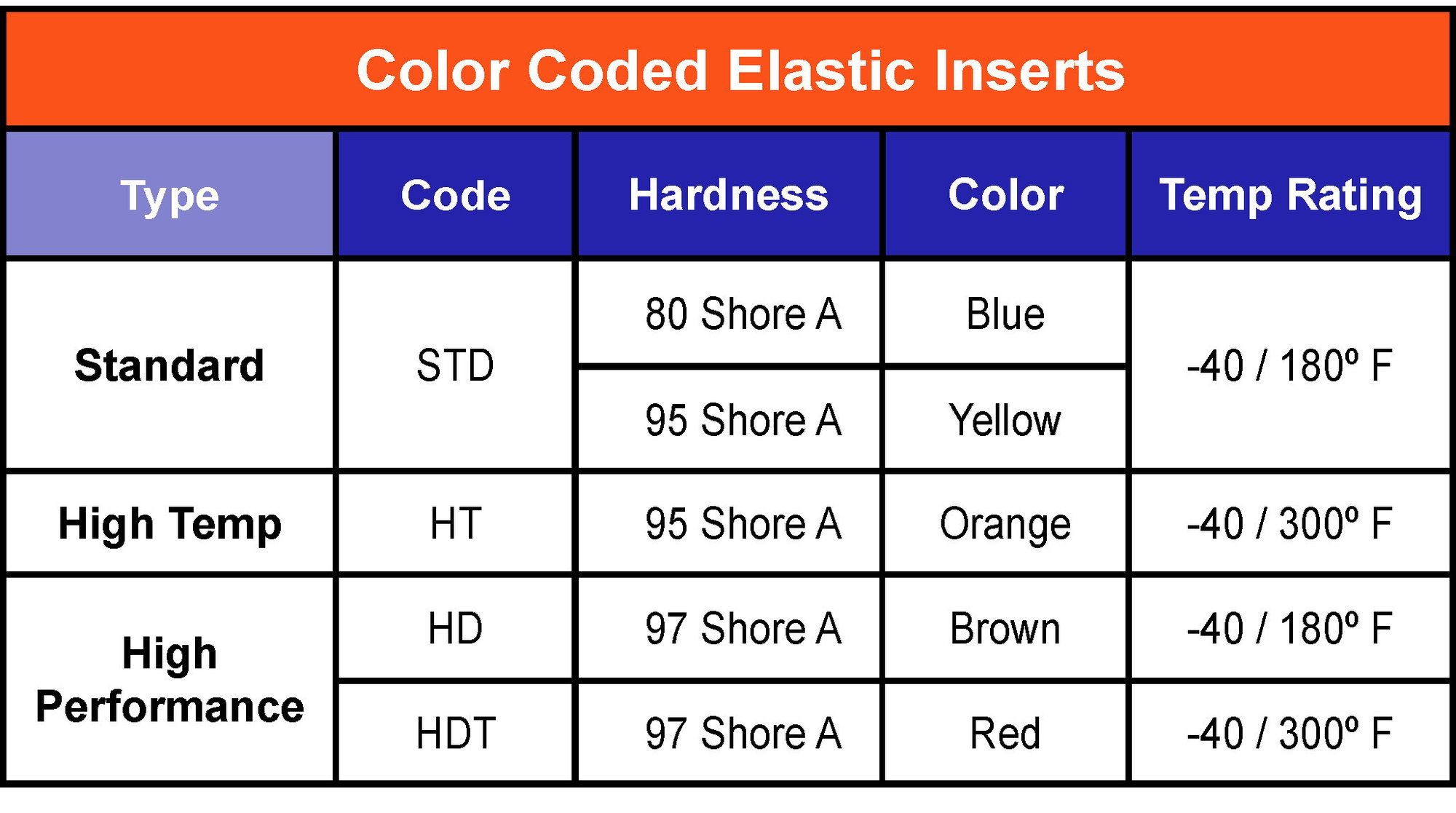

Samiflex Elastomeric Inserts

The insert is manufactured using a unique polyurethane blend in three compounds and three hardness ratings, allowing the insert to meet or exceed your application requirements.

The standard (Yellow) insert has a hardness rating of 95 Shore A.

High-performance inserts type HD (brown) and HDT (red) enable torque ratings to be increased by 40%.

Contact CDWdrives for assistance with sizing and selection.

SAMiGUARD

The SAMiGUARD is a new overload protection system designed to address the drawbacks of conventional shear pins. It uses a tapered pin (fuse) to overcome issues such as pin fatigue, fretting, and uncertainty in load sharing. This innovative system aims to enhance safety and minimize downtime in process plants.

Advantages:

- Easy access - the drive is reset in minutes, and only the fuse is replaced

- Taper construction gives maximum rigidity with no wear from backlash

- Clamping screws give favorable axial location; shear neck cannot be displaced from correct position between flanges

- Equal load sharing with multiple fuses in high-torque drives

- Very high capacity within compact dimensions

- Shear necks are standardized and color-coded, giving safe, tamper-proof repeatability and spare economy

- "Fail-safe" under all conditions.

- Not affected by changes in temperature or humidity

- Ability to release not dependent on lubrication