4 min read

Understanding the Importance of Torque Limiters

Diann Sobolewski Sobolewski : Sep 30, 2024 9:47:29 AM

Why Torque Limiters are Essential

Whether simple or complex, modern machines share a predictable motion known as torque or force and velocity control. An inherent problem exists when these machines encounter an unexpected force, such as a jam or tool breakage, that exceeds the machine components' design limits, potentially damaging the machine and workpiece. Torque limiters play a crucial role in preventing potential failures by executing a controlled decoupling of the unexpected force, thereby maintaining the machine's integrity. This article will cover the benefits of using a torque limiter, selecting and placing a torque limiter, and the types of torque limiters and their applications.

Benefits of Using a Torque Limiter

Torque limiters are not limited to a specific type of machinery. Their versatility is a key benefit, making them crucial in designing machines and protecting against damage and costly downtime caused by machine overloads and failures. They function as a 1:1 transmission if the torque is less than a specified value and as a clutch when the torque surpasses the limit. This quick disconnection of the drive from the driven system, typically in milliseconds, removes much of the inertial energy from the drive train. Torque limiters are used in a wide range of applications and are suitable for a variety of industries, including conveyors, assembly lines, packaging machinery, machine tools, textile machinery, woodworking machines, industrial robots, sheet metal processing equipment, wastewater treatment facilities, printing machines, and servo and DC motor drives to name a few. Their role in preventing costly downtime is a significant advantage for any industry.

Selecting and Placement of a Torque Limiter

The most crucial criterion for selecting a torque limiter is the drive torque. This criterion is of utmost importance and is key to the selection process. Torque limiters span a wide range of rated torque — from less than 1 N-m to over 10,000 kN-m. In multi-component mechanisms, the placement of the torque limiter determines which components are protected. The torque limiter can be located at various points along the drive train and set to decouple the driven components from the driving components. For instance, placing a torque limiter between the output of a gearbox and the driven load protects both the gearbox and motor from overload. Alternatively, you could use a lower torque-rated limiter between the gearbox and the motor, which would only protect the motor from damage. Best practices dictate locating the torque limiter to protect the most expensive component of the drive train.

The torque load determines the limiter's size, type, and cost. Ideally, the torque limiter should be selected or adjusted to slip at a high enough torque to avoid unnecessary tripping, such as during initial machine startup, which is typically the point of highest torque under normal operating conditions. It is best to keep the torque limiter operating where the shaft speed is relatively low for extended service life.

Shear Pin Torque Limiter

A shear pin torque limiter is a mechanical device that uses shear pins to connect two rotating bodies, such as a collar and sprocket or two coupling halves. It is designed to break at a specific torque level to separate the drive system from the load, protecting more expensive or less easily replaced parts from damage.

Sear pin torque limiter - Altra Motion

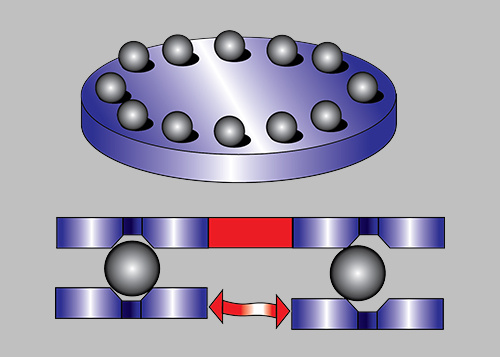

Ball Detent Torque Limiters

A ball detent torque limiter uses a series of balls or rollers positioned in mating sockets to connect the drive and driven elements and hold them in position under normal operating conditions by spring force. When a torque overload occurs, the balls/rollers overcome the spring pressure, forcing the drive and driven element apart. Some ball detent torque limiters use pneumatic technology instead of springs to engage the torque limiter. The advantage of the pneumatic approach is that the trip-out torque can be remotely controlled by air pressure adjustment to increase or reduce the set torque. CDWdrives manufactures high-quality ball detent torque limiters. We have four popular sizes in stock that ship the next day. As experts in torque limiters, CDWdrives can quickly build and ship custom configurations to meet your specific application needs.

CDWdrives Ball Detent torque limiter

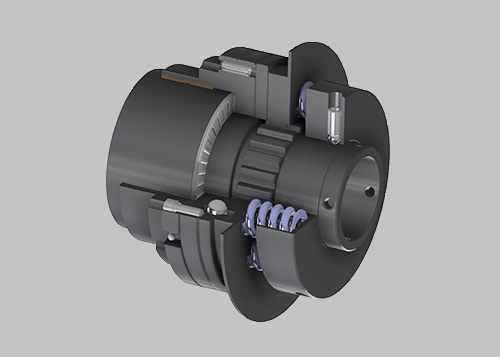

Friction Torque Limiter

Friction torque limiters, or friction brakes and overload clutches, function similarly to automotive brakes. They consist of a drive component sandwiched between friction linings connected to a driven component and transmit power until a preset limit is reached. When the limit is attained, and an overload occurs, the drive component slips relative to the friction linings, transmitting only partial power. This protects the machine from damage. Once the overload is no longer present, the drive resumes transmitting torque. The disadvantage of this style of torque limiters is that they wear over time and require occasional maintenance.

PT TECH - SLQ Series Friction Torque Limiter

Hydraulic Torque Limiters

Hydraulic torque limiters apply hydraulic pressure between the drive and driven elements of the torque converter to connect the power source to the load. When the input load exceeds the desired release torque, the hydraulic pressure is no longer sufficient, causing the driven element to slip against the driving element. Hydraulic torque limiters are primarily used in very high-torque applications.

Electromagnetic Clutches

Electromagnetic Clutches can be used as torque limiters in certain applications. In this type of device, the drive and driven elements do not touch each other. Instead, they are connected through electromagnets that exert force at a distance. These devices reduce the transmission of torsional vibrations. The torque settings are linearly related to the current passing through the windings. The benefits of this torque limiter are that it is resistant to wear, does not require lubricant, has a fast response time, torque is easily and quickly controlled, and can be used at nearly any temperature.

An alternative approach is to electronically monitor the torque output at the motor and apply a braking torque when an overage is detected. This approach is well-suited when the load increases linearly at a relatively slow

Conclusion

Mechanical torque limiters help the machine designer protect the equipment and operator against damage due to overloads. CDWdrives can assist you in selecting the appropriate style and size of torque limiter for your specific application, which will protect your machine against damage at a relatively low cost. Our sales representatives are backed by a team of engineers who are torque limiter specialists. We carry numerous high-quality torque limiters from leading manufacturers adaptable to nearly any industry.

Contact CDWdrives: 586-949-5474 sales@cdwdrives.com